Welcome to our Skinny Zone Forum!

It is our desire that this forum will add to the enjoyment of its users and bring you even closer to attaining your health goals. We believe there is great value in being a part of a strong, like minded community when striving to reach specific goals. We hope this will be a great tool for you to launch further into finding your own personal Skinny Zone! Reach it – Live it – Keep it!

**Although there will no doubt, be valuable information here from experienced users of the Skinny Zone products you must keep in mind that the information shared by each individual is their own expressed opinion based on the individual’s experiences and/or opinions and are not necessarily the view of Skinny Zone – by Bona Sano Co Inc. Any statement, opinion, or expression made here is not intended to diagnose, treat, cure, or prevent any disease. Please perform your own due diligence in assessing the appropriate use of the information provided.

Tundish Metering Nozzles: Definition and Purpose

Quote from hyrefractory on December 26, 2025, 2:25 am

Introduction

A tundish metering nozzle is a specialized refractory component used in continuous casting of molten metal — most commonly steel — to control and meter the flow of liquid metal from the tundish into the mold or submerged-entry nozzle. It is a short, high-temperature flow channel engineered to deliver a steady, predictable stream of metal while resisting the combined effects of corrosion, erosion, thermal shock and mechanical wear. Proper selection, installation and management of tundish metering nozzles are essential to casting stability, product quality and safe, economical operation of a continuous caster.

This article presents a technical treatment of the tundish metering nozzle for an engineering or metallurgical audience. It covers definition and purpose, how the nozzle operates within the continuous-casting system, common designs and materials, design and manufacturing considerations, typical service problems and mitigation measures, maintenance best practices, and recent technological developments.

Purpose and role in continuous casting

In continuous casting, a ladle pours molten metal into the tundish, an intermediate vessel that buffers flow and promotes inclusion flotation and temperature equalization. The tundish metering nozzle is the controlled outlet between this buffer and the downstream mold or submerged-entry nozzle. Its principal functions are:

- Flow metering: provide a predictable cross-sectional area and geometry so that, for a given head in the tundish, the stream rate matches target casting speed.

- Flow conditioning: reduce turbulence or undesirable jet shape that could entrain slag, trap flux, or produce unstable mold flow patterns that lead to shell defects.

- Isolation and shutoff interface: in systems with slide gates or stopper rods, the nozzle forms the housing and sealing surface that enables rapid shutoff or fine flow adjustment.

- Mechanical and thermal protection: act as a sacrificial lining that isolates structural tundish components from direct exposure to corrosive slag and molten metal.

Because continuous casting demands steady, repeatable delivery of liquid metal for long sequences, the metering nozzle is often a life-limiting consumable and a key reliability concern.

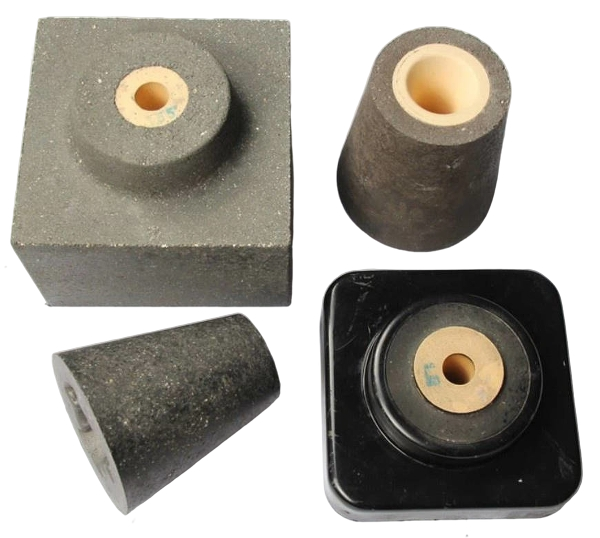

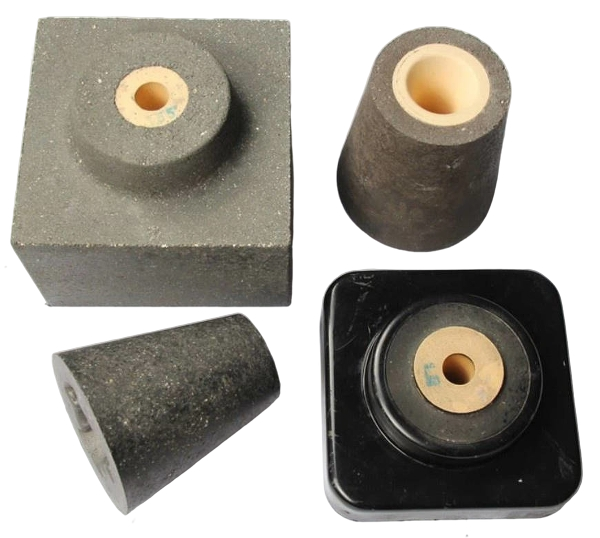

Nozzle types and typical materials

Common types

- Fixed orifices (sizing nozzles): simple monolithic or multi-piece nozzles with a calibrated bore. Flow is primarily controlled by bore diameter and tundish head. Frequently used for stable, long-sequence runs where minimal moving parts are desirable.

- Insert and composite nozzles: a hard, low-porosity insert (commonly zirconia) is fitted into an outer support block (commonly alumina or magnesia-based). This provides a durable flow surface while keeping cost and mechanical support manageable.

- Housing for slide gates / stopper rod systems: the nozzle assembly may incorporate slide-gate plates or a vertical stopper rod mechanism that provides variable throttling and rapid shutoff.

- Stepped, tapered or shaped bores: geometries engineered to control jet shape and velocity profile as it leaves the tundish.

Typical refractory materials

- Stabilized zirconia (ZrO₂): prized for high-temperature strength, thermal shock resistance and low wettability. Often used as the insert or flow-facing material.

- Alumina-based ceramics (Al₂O₃ and Al₂O₃–C): widely used for outer bodies and some nozzles due to good mechanical properties and lower cost; Al₂O₃–C offers improved thermal shock resistance.

- Magnesia (MgO) and magnesia–alumina blends: chosen where chemical compatibility with specific steels or slags requires a more basic refractory.

- Composite/graded structures: combinations of the above, engineered for graded thermal and mechanical properties (dense wear face, supportive backing, controlled porosity).

Material choice reflects an economic balance among lifetime, vulnerability to specific slags or inclusions, manufacturability and interchangeability with quick-change systems.

Design and manufacturing considerations

Designing an effective tundish metering nozzle requires integrated consideration of fluid mechanics, thermal behavior and refractory processing:

- Flow dynamics: bore diameter, taper, outlet shape and any internal flow features determine velocity profile, jet coherence and pressure drop. Designs aim to minimize recirculation zones and high-shear regions that promote inclusion entrapment and refractory erosion.

- Thermal and mechanical stresses: the nozzle must survive the thermal gradient at start-up/shutdown and resist shock from rapid temperature changes. Geometry and material selection must anticipate these stresses.

- Sealing and gas-tightness: joints and seating faces must prevent air aspiration and metal leakage. Composite designs often avoid cemented joints and use pressed-fit or isostatically formed interfaces to maintain gas-tight integrity.

- Manufacturing tolerances and QC: accurate bore geometry, absence of cracks, controlled porosity and consistent density are essential. Sintering, pressing and machining processes must be tightly controlled; nondestructive inspection (visual, ultrasonic or X-ray) is frequently used.

- Serviceability: designs that permit fast replacement of the lower nozzle segment or rapid engagement of a spare nozzle reduce downtime. Standardized dimensions and integration with nozzle-change mechanisms are practical design considerations.

Common service problems and root causes

Clogging and plugging

Clogging is one of the most consequential and frequent nozzle issues. Causes include:

- Inclusion deposition: non-metallic particles (oxides, alumina agglomerates, sulfides) attach to walls or the orifice and accumulate.

- Local freezing / solidification: inadequate preheating or local cooling produces freeze rings or solidification within the bore.

- Chemical build-up: reactions between slag constituents and refractory may form low-melting compounds that solidify in situ.

Consequences of clogging include distorted mold flow, partial or complete flow interruption, inclusion entrainment, surface defects and unplanned casting stoppages.

Erosion and chemical corrosion

High-velocity jets and abrasive inclusions abrade the bore. Corrosive slags attack refractory phases, causing pitting, thinning, or gradual enlargement of the orifice which alters flow rates and increases the risk of catastrophic failure.

Thermal shock and cracking

Rapid temperature changes, especially when pouring into cold nozzles or stopping and restarting, can crack refractory components, degrading seals and creating leakage paths or fragmentation that contributes to clogging.

Misalignment and installation defects

Poor seating, tilting or inadequate ramming around the nozzle permits air aspiration, uneven wear and premature failure. Mechanical stresses from improper clamping or thermal expansion mismatches can also damage the assembly.

Operational measures to maximize life and reliability

Practical practices that operators use include:

- Preheating: consistent, adequate preheat to prevent freezing and reduce thermal shock risk is critical. Preheating spares reduces changeover risk.

- Proper installation and alignment: ensure vertical orientation, correct seating, and appropriate ramming to create a gas-tight fit.

- Argon purging and controlled gas management: argon purge through the nozzle or auxiliary ports helps float inclusions away from the orifice and establishes a protective film to reduce refractory contact and sticking; purge rates must be optimized to avoid gas entrapment in the cast product.

- Monitoring: back-pressure on purge lines, mold level behavior, gas composition (nitrogen uptake) and other process indicators provide early warning of nozzle deterioration or leakage.

- Routine inspection and scheduled replacement: proactive replacement before catastrophic wear or frequent inspection during long sequences reduces unplanned outages.

- Emergency response protocols: clear procedures for partial leaks, plug detection and safe shutdown minimize risk to personnel and equipment in case of failure.

Technological advances

Recent innovations target longer life, faster changeover and lower defect rates:

- Advanced insert materials and graded composites: engineered zirconia and multi-layer inserts deliver superior wear resistance and reduced inclusion adhesion.

- Quick-change nozzle systems: mechanical changers or cartridge systems permit rapid swap-out of the lower nozzle element during production, minimizing downtime.

- Surface treatments and coatings: thin, inert ceramic coatings or engineered slurries applied prior to casting reduce inclusion sticking and initial wear.

- Optimized flow geometries: computational modeling and scale-model experiments have refined outlet shapes that produce laminar, low-shear jets and improved inclusion transport characteristics.

- Instrumentation and automation: improved sensing (pressure, acoustic, thermal) and automated control of purge and gate systems provide earlier detection and more consistent management of nozzle condition.

Conclusion

The tundish metering nozzle is a small but critical element in the continuous casting chain. Its design, material composition and operational management directly influence casting stability, product quality and overall plant productivity. Understanding the interplay among flow dynamics, refractory behavior and practical maintenance strategies is essential for metallurgical engineers and operators tasked with improving uptime and reducing casting defects. Modern developments — from advanced zirconia inserts to rapid-change mechanics and digital monitoring — continue to push nozzle reliability forward, but diligent preheating, proper installation and proactive monitoring remain the most effective tools to avoid the recurring problems of clogging, erosion and thermal failure

by adam wang - Friday, 26 December 2025, 5:18 PMAnyone on this site

Introduction

A tundish metering nozzle is a specialized refractory component used in continuous casting of molten metal — most commonly steel — to control and meter the flow of liquid metal from the tundish into the mold or submerged-entry nozzle. It is a short, high-temperature flow channel engineered to deliver a steady, predictable stream of metal while resisting the combined effects of corrosion, erosion, thermal shock and mechanical wear. Proper selection, installation and management of tundish metering nozzles are essential to casting stability, product quality and safe, economical operation of a continuous caster.

This article presents a technical treatment of the tundish metering nozzle for an engineering or metallurgical audience. It covers definition and purpose, how the nozzle operates within the continuous-casting system, common designs and materials, design and manufacturing considerations, typical service problems and mitigation measures, maintenance best practices, and recent technological developments.

Purpose and role in continuous casting

In continuous casting, a ladle pours molten metal into the tundish, an intermediate vessel that buffers flow and promotes inclusion flotation and temperature equalization. The tundish metering nozzle is the controlled outlet between this buffer and the downstream mold or submerged-entry nozzle. Its principal functions are:

- Flow metering: provide a predictable cross-sectional area and geometry so that, for a given head in the tundish, the stream rate matches target casting speed.

- Flow conditioning: reduce turbulence or undesirable jet shape that could entrain slag, trap flux, or produce unstable mold flow patterns that lead to shell defects.

- Isolation and shutoff interface: in systems with slide gates or stopper rods, the nozzle forms the housing and sealing surface that enables rapid shutoff or fine flow adjustment.

- Mechanical and thermal protection: act as a sacrificial lining that isolates structural tundish components from direct exposure to corrosive slag and molten metal.

Because continuous casting demands steady, repeatable delivery of liquid metal for long sequences, the metering nozzle is often a life-limiting consumable and a key reliability concern.

Nozzle types and typical materials

Common types

- Fixed orifices (sizing nozzles): simple monolithic or multi-piece nozzles with a calibrated bore. Flow is primarily controlled by bore diameter and tundish head. Frequently used for stable, long-sequence runs where minimal moving parts are desirable.

- Insert and composite nozzles: a hard, low-porosity insert (commonly zirconia) is fitted into an outer support block (commonly alumina or magnesia-based). This provides a durable flow surface while keeping cost and mechanical support manageable.

- Housing for slide gates / stopper rod systems: the nozzle assembly may incorporate slide-gate plates or a vertical stopper rod mechanism that provides variable throttling and rapid shutoff.

- Stepped, tapered or shaped bores: geometries engineered to control jet shape and velocity profile as it leaves the tundish.

Typical refractory materials

- Stabilized zirconia (ZrO₂): prized for high-temperature strength, thermal shock resistance and low wettability. Often used as the insert or flow-facing material.

- Alumina-based ceramics (Al₂O₃ and Al₂O₃–C): widely used for outer bodies and some nozzles due to good mechanical properties and lower cost; Al₂O₃–C offers improved thermal shock resistance.

- Magnesia (MgO) and magnesia–alumina blends: chosen where chemical compatibility with specific steels or slags requires a more basic refractory.

- Composite/graded structures: combinations of the above, engineered for graded thermal and mechanical properties (dense wear face, supportive backing, controlled porosity).

Material choice reflects an economic balance among lifetime, vulnerability to specific slags or inclusions, manufacturability and interchangeability with quick-change systems.

Design and manufacturing considerations

Designing an effective tundish metering nozzle requires integrated consideration of fluid mechanics, thermal behavior and refractory processing:

- Flow dynamics: bore diameter, taper, outlet shape and any internal flow features determine velocity profile, jet coherence and pressure drop. Designs aim to minimize recirculation zones and high-shear regions that promote inclusion entrapment and refractory erosion.

- Thermal and mechanical stresses: the nozzle must survive the thermal gradient at start-up/shutdown and resist shock from rapid temperature changes. Geometry and material selection must anticipate these stresses.

- Sealing and gas-tightness: joints and seating faces must prevent air aspiration and metal leakage. Composite designs often avoid cemented joints and use pressed-fit or isostatically formed interfaces to maintain gas-tight integrity.

- Manufacturing tolerances and QC: accurate bore geometry, absence of cracks, controlled porosity and consistent density are essential. Sintering, pressing and machining processes must be tightly controlled; nondestructive inspection (visual, ultrasonic or X-ray) is frequently used.

- Serviceability: designs that permit fast replacement of the lower nozzle segment or rapid engagement of a spare nozzle reduce downtime. Standardized dimensions and integration with nozzle-change mechanisms are practical design considerations.

Common service problems and root causes

Clogging and plugging

Clogging is one of the most consequential and frequent nozzle issues. Causes include:

- Inclusion deposition: non-metallic particles (oxides, alumina agglomerates, sulfides) attach to walls or the orifice and accumulate.

- Local freezing / solidification: inadequate preheating or local cooling produces freeze rings or solidification within the bore.

- Chemical build-up: reactions between slag constituents and refractory may form low-melting compounds that solidify in situ.

Consequences of clogging include distorted mold flow, partial or complete flow interruption, inclusion entrainment, surface defects and unplanned casting stoppages.

Erosion and chemical corrosion

High-velocity jets and abrasive inclusions abrade the bore. Corrosive slags attack refractory phases, causing pitting, thinning, or gradual enlargement of the orifice which alters flow rates and increases the risk of catastrophic failure.

Thermal shock and cracking

Rapid temperature changes, especially when pouring into cold nozzles or stopping and restarting, can crack refractory components, degrading seals and creating leakage paths or fragmentation that contributes to clogging.

Misalignment and installation defects

Poor seating, tilting or inadequate ramming around the nozzle permits air aspiration, uneven wear and premature failure. Mechanical stresses from improper clamping or thermal expansion mismatches can also damage the assembly.

Operational measures to maximize life and reliability

Practical practices that operators use include:

- Preheating: consistent, adequate preheat to prevent freezing and reduce thermal shock risk is critical. Preheating spares reduces changeover risk.

- Proper installation and alignment: ensure vertical orientation, correct seating, and appropriate ramming to create a gas-tight fit.

- Argon purging and controlled gas management: argon purge through the nozzle or auxiliary ports helps float inclusions away from the orifice and establishes a protective film to reduce refractory contact and sticking; purge rates must be optimized to avoid gas entrapment in the cast product.

- Monitoring: back-pressure on purge lines, mold level behavior, gas composition (nitrogen uptake) and other process indicators provide early warning of nozzle deterioration or leakage.

- Routine inspection and scheduled replacement: proactive replacement before catastrophic wear or frequent inspection during long sequences reduces unplanned outages.

- Emergency response protocols: clear procedures for partial leaks, plug detection and safe shutdown minimize risk to personnel and equipment in case of failure.

Technological advances

Recent innovations target longer life, faster changeover and lower defect rates:

- Advanced insert materials and graded composites: engineered zirconia and multi-layer inserts deliver superior wear resistance and reduced inclusion adhesion.

- Quick-change nozzle systems: mechanical changers or cartridge systems permit rapid swap-out of the lower nozzle element during production, minimizing downtime.

- Surface treatments and coatings: thin, inert ceramic coatings or engineered slurries applied prior to casting reduce inclusion sticking and initial wear.

- Optimized flow geometries: computational modeling and scale-model experiments have refined outlet shapes that produce laminar, low-shear jets and improved inclusion transport characteristics.

- Instrumentation and automation: improved sensing (pressure, acoustic, thermal) and automated control of purge and gate systems provide earlier detection and more consistent management of nozzle condition.

Conclusion

The tundish metering nozzle is a small but critical element in the continuous casting chain. Its design, material composition and operational management directly influence casting stability, product quality and overall plant productivity. Understanding the interplay among flow dynamics, refractory behavior and practical maintenance strategies is essential for metallurgical engineers and operators tasked with improving uptime and reducing casting defects. Modern developments — from advanced zirconia inserts to rapid-change mechanics and digital monitoring — continue to push nozzle reliability forward, but diligent preheating, proper installation and proactive monitoring remain the most effective tools to avoid the recurring problems of clogging, erosion and thermal failure

Tips You Shuold Know About The Tundish Metering Nozzle

Introduction To The Fast Change Mechanism Of Tundish Metering Nozzle

. Tundish Metering Nozzle&Zirconia Inserts

What Is The Composition Of Sub Entry Nozzle(SEN)

Ladle Shroud Gasket – Material, Function, Shape & Installation Guide

Introduction

A tundish metering nozzle is a specialized refractory component used in continuous casting of molten metal — most commonly steel — to control and meter the flow of liquid metal from the tundish into the mold or submerged-entry nozzle. It is a short, high-temperature flow channel engineered to deliver a steady, predictable stream of metal while resisting the combined effects of corrosion, erosion, thermal shock and mechanical wear. Proper selection, installation and management of tundish metering nozzles are essential to casting stability, product quality and safe, economical operation of a continuous caster.

This article presents a technical treatment of the tundish metering nozzle for an engineering or metallurgical audience. It covers definition and purpose, how the nozzle operates within the continuous-casting system, common designs and materials, design and manufacturing considerations, typical service problems and mitigation measures, maintenance best practices, and recent technological developments.

Purpose and role in continuous casting

In continuous casting, a ladle pours molten metal into the tundish, an intermediate vessel that buffers flow and promotes inclusion flotation and temperature equalization. The tundish metering nozzle is the controlled outlet between this buffer and the downstream mold or submerged-entry nozzle. Its principal functions are:

- Flow metering: provide a predictable cross-sectional area and geometry so that, for a given head in the tundish, the stream rate matches target casting speed.

- Flow conditioning: reduce turbulence or undesirable jet shape that could entrain slag, trap flux, or produce unstable mold flow patterns that lead to shell defects.

- Isolation and shutoff interface: in systems with slide gates or stopper rods, the nozzle forms the housing and sealing surface that enables rapid shutoff or fine flow adjustment.

- Mechanical and thermal protection: act as a sacrificial lining that isolates structural tundish components from direct exposure to corrosive slag and molten metal.

Because continuous casting demands steady, repeatable delivery of liquid metal for long sequences, the metering nozzle is often a life-limiting consumable and a key reliability concern.

Nozzle types and typical materials

Common types

- Fixed orifices (sizing nozzles): simple monolithic or multi-piece nozzles with a calibrated bore. Flow is primarily controlled by bore diameter and tundish head. Frequently used for stable, long-sequence runs where minimal moving parts are desirable.

- Insert and composite nozzles: a hard, low-porosity insert (commonly zirconia) is fitted into an outer support block (commonly alumina or magnesia-based). This provides a durable flow surface while keeping cost and mechanical support manageable.

- Housing for slide gates / stopper rod systems: the nozzle assembly may incorporate slide-gate plates or a vertical stopper rod mechanism that provides variable throttling and rapid shutoff.

- Stepped, tapered or shaped bores: geometries engineered to control jet shape and velocity profile as it leaves the tundish.

Typical refractory materials

- Stabilized zirconia (ZrO₂): prized for high-temperature strength, thermal shock resistance and low wettability. Often used as the insert or flow-facing material.

- Alumina-based ceramics (Al₂O₃ and Al₂O₃–C): widely used for outer bodies and some nozzles due to good mechanical properties and lower cost; Al₂O₃–C offers improved thermal shock resistance.

- Magnesia (MgO) and magnesia–alumina blends: chosen where chemical compatibility with specific steels or slags requires a more basic refractory.

- Composite/graded structures: combinations of the above, engineered for graded thermal and mechanical properties (dense wear face, supportive backing, controlled porosity).

Material choice reflects an economic balance among lifetime, vulnerability to specific slags or inclusions, manufacturability and interchangeability with quick-change systems.

Design and manufacturing considerations

Designing an effective tundish metering nozzle requires integrated consideration of fluid mechanics, thermal behavior and refractory processing:

- Flow dynamics: bore diameter, taper, outlet shape and any internal flow features determine velocity profile, jet coherence and pressure drop. Designs aim to minimize recirculation zones and high-shear regions that promote inclusion entrapment and refractory erosion.

- Thermal and mechanical stresses: the nozzle must survive the thermal gradient at start-up/shutdown and resist shock from rapid temperature changes. Geometry and material selection must anticipate these stresses.

- Sealing and gas-tightness: joints and seating faces must prevent air aspiration and metal leakage. Composite designs often avoid cemented joints and use pressed-fit or isostatically formed interfaces to maintain gas-tight integrity.

- Manufacturing tolerances and QC: accurate bore geometry, absence of cracks, controlled porosity and consistent density are essential. Sintering, pressing and machining processes must be tightly controlled; nondestructive inspection (visual, ultrasonic or X-ray) is frequently used.

- Serviceability: designs that permit fast replacement of the lower nozzle segment or rapid engagement of a spare nozzle reduce downtime. Standardized dimensions and integration with nozzle-change mechanisms are practical design considerations.

Common service problems and root causes

Clogging and plugging

Clogging is one of the most consequential and frequent nozzle issues. Causes include:

- Inclusion deposition: non-metallic particles (oxides, alumina agglomerates, sulfides) attach to walls or the orifice and accumulate.

- Local freezing / solidification: inadequate preheating or local cooling produces freeze rings or solidification within the bore.

- Chemical build-up: reactions between slag constituents and refractory may form low-melting compounds that solidify in situ.

Consequences of clogging include distorted mold flow, partial or complete flow interruption, inclusion entrainment, surface defects and unplanned casting stoppages.

Erosion and chemical corrosion

High-velocity jets and abrasive inclusions abrade the bore. Corrosive slags attack refractory phases, causing pitting, thinning, or gradual enlargement of the orifice which alters flow rates and increases the risk of catastrophic failure.

Thermal shock and cracking

Rapid temperature changes, especially when pouring into cold nozzles or stopping and restarting, can crack refractory components, degrading seals and creating leakage paths or fragmentation that contributes to clogging.

Misalignment and installation defects

Poor seating, tilting or inadequate ramming around the nozzle permits air aspiration, uneven wear and premature failure. Mechanical stresses from improper clamping or thermal expansion mismatches can also damage the assembly.

Operational measures to maximize life and reliability

Practical practices that operators use include:

- Preheating: consistent, adequate preheat to prevent freezing and reduce thermal shock risk is critical. Preheating spares reduces changeover risk.

- Proper installation and alignment: ensure vertical orientation, correct seating, and appropriate ramming to create a gas-tight fit.

- Argon purging and controlled gas management: argon purge through the nozzle or auxiliary ports helps float inclusions away from the orifice and establishes a protective film to reduce refractory contact and sticking; purge rates must be optimized to avoid gas entrapment in the cast product.

- Monitoring: back-pressure on purge lines, mold level behavior, gas composition (nitrogen uptake) and other process indicators provide early warning of nozzle deterioration or leakage.

- Routine inspection and scheduled replacement: proactive replacement before catastrophic wear or frequent inspection during long sequences reduces unplanned outages.

- Emergency response protocols: clear procedures for partial leaks, plug detection and safe shutdown minimize risk to personnel and equipment in case of failure.

Technological advances

Recent innovations target longer life, faster changeover and lower defect rates:

- Advanced insert materials and graded composites: engineered zirconia and multi-layer inserts deliver superior wear resistance and reduced inclusion adhesion.

- Quick-change nozzle systems: mechanical changers or cartridge systems permit rapid swap-out of the lower nozzle element during production, minimizing downtime.

- Surface treatments and coatings: thin, inert ceramic coatings or engineered slurries applied prior to casting reduce inclusion sticking and initial wear.

- Optimized flow geometries: computational modeling and scale-model experiments have refined outlet shapes that produce laminar, low-shear jets and improved inclusion transport characteristics.

- Instrumentation and automation: improved sensing (pressure, acoustic, thermal) and automated control of purge and gate systems provide earlier detection and more consistent management of nozzle condition.

Conclusion

The tundish metering nozzle is a small but critical element in the continuous casting chain. Its design, material composition and operational management directly influence casting stability, product quality and overall plant productivity. Understanding the interplay among flow dynamics, refractory behavior and practical maintenance strategies is essential for metallurgical engineers and operators tasked with improving uptime and reducing casting defects. Modern developments — from advanced zirconia inserts to rapid-change mechanics and digital monitoring — continue to push nozzle reliability forward, but diligent preheating, proper installation and proactive monitoring remain the most effective tools to avoid the recurring problems of clogging, erosion and thermal failure

Introduction

A tundish metering nozzle is a specialized refractory component used in continuous casting of molten metal — most commonly steel — to control and meter the flow of liquid metal from the tundish into the mold or submerged-entry nozzle. It is a short, high-temperature flow channel engineered to deliver a steady, predictable stream of metal while resisting the combined effects of corrosion, erosion, thermal shock and mechanical wear. Proper selection, installation and management of tundish metering nozzles are essential to casting stability, product quality and safe, economical operation of a continuous caster.

This article presents a technical treatment of the tundish metering nozzle for an engineering or metallurgical audience. It covers definition and purpose, how the nozzle operates within the continuous-casting system, common designs and materials, design and manufacturing considerations, typical service problems and mitigation measures, maintenance best practices, and recent technological developments.

Purpose and role in continuous casting

In continuous casting, a ladle pours molten metal into the tundish, an intermediate vessel that buffers flow and promotes inclusion flotation and temperature equalization. The tundish metering nozzle is the controlled outlet between this buffer and the downstream mold or submerged-entry nozzle. Its principal functions are:

- Flow metering: provide a predictable cross-sectional area and geometry so that, for a given head in the tundish, the stream rate matches target casting speed.

- Flow conditioning: reduce turbulence or undesirable jet shape that could entrain slag, trap flux, or produce unstable mold flow patterns that lead to shell defects.

- Isolation and shutoff interface: in systems with slide gates or stopper rods, the nozzle forms the housing and sealing surface that enables rapid shutoff or fine flow adjustment.

- Mechanical and thermal protection: act as a sacrificial lining that isolates structural tundish components from direct exposure to corrosive slag and molten metal.

Because continuous casting demands steady, repeatable delivery of liquid metal for long sequences, the metering nozzle is often a life-limiting consumable and a key reliability concern.

Nozzle types and typical materials

Common types

- Fixed orifices (sizing nozzles): simple monolithic or multi-piece nozzles with a calibrated bore. Flow is primarily controlled by bore diameter and tundish head. Frequently used for stable, long-sequence runs where minimal moving parts are desirable.

- Insert and composite nozzles: a hard, low-porosity insert (commonly zirconia) is fitted into an outer support block (commonly alumina or magnesia-based). This provides a durable flow surface while keeping cost and mechanical support manageable.

- Housing for slide gates / stopper rod systems: the nozzle assembly may incorporate slide-gate plates or a vertical stopper rod mechanism that provides variable throttling and rapid shutoff.

- Stepped, tapered or shaped bores: geometries engineered to control jet shape and velocity profile as it leaves the tundish.

Typical refractory materials

- Stabilized zirconia (ZrO₂): prized for high-temperature strength, thermal shock resistance and low wettability. Often used as the insert or flow-facing material.

- Alumina-based ceramics (Al₂O₃ and Al₂O₃–C): widely used for outer bodies and some nozzles due to good mechanical properties and lower cost; Al₂O₃–C offers improved thermal shock resistance.

- Magnesia (MgO) and magnesia–alumina blends: chosen where chemical compatibility with specific steels or slags requires a more basic refractory.

- Composite/graded structures: combinations of the above, engineered for graded thermal and mechanical properties (dense wear face, supportive backing, controlled porosity).

Material choice reflects an economic balance among lifetime, vulnerability to specific slags or inclusions, manufacturability and interchangeability with quick-change systems.

Design and manufacturing considerations

Designing an effective tundish metering nozzle requires integrated consideration of fluid mechanics, thermal behavior and refractory processing:

- Flow dynamics: bore diameter, taper, outlet shape and any internal flow features determine velocity profile, jet coherence and pressure drop. Designs aim to minimize recirculation zones and high-shear regions that promote inclusion entrapment and refractory erosion.

- Thermal and mechanical stresses: the nozzle must survive the thermal gradient at start-up/shutdown and resist shock from rapid temperature changes. Geometry and material selection must anticipate these stresses.

- Sealing and gas-tightness: joints and seating faces must prevent air aspiration and metal leakage. Composite designs often avoid cemented joints and use pressed-fit or isostatically formed interfaces to maintain gas-tight integrity.

- Manufacturing tolerances and QC: accurate bore geometry, absence of cracks, controlled porosity and consistent density are essential. Sintering, pressing and machining processes must be tightly controlled; nondestructive inspection (visual, ultrasonic or X-ray) is frequently used.

- Serviceability: designs that permit fast replacement of the lower nozzle segment or rapid engagement of a spare nozzle reduce downtime. Standardized dimensions and integration with nozzle-change mechanisms are practical design considerations.

Common service problems and root causes

Clogging and plugging

Clogging is one of the most consequential and frequent nozzle issues. Causes include:

- Inclusion deposition: non-metallic particles (oxides, alumina agglomerates, sulfides) attach to walls or the orifice and accumulate.

- Local freezing / solidification: inadequate preheating or local cooling produces freeze rings or solidification within the bore.

- Chemical build-up: reactions between slag constituents and refractory may form low-melting compounds that solidify in situ.

Consequences of clogging include distorted mold flow, partial or complete flow interruption, inclusion entrainment, surface defects and unplanned casting stoppages.

Erosion and chemical corrosion

High-velocity jets and abrasive inclusions abrade the bore. Corrosive slags attack refractory phases, causing pitting, thinning, or gradual enlargement of the orifice which alters flow rates and increases the risk of catastrophic failure.

Thermal shock and cracking

Rapid temperature changes, especially when pouring into cold nozzles or stopping and restarting, can crack refractory components, degrading seals and creating leakage paths or fragmentation that contributes to clogging.

Misalignment and installation defects

Poor seating, tilting or inadequate ramming around the nozzle permits air aspiration, uneven wear and premature failure. Mechanical stresses from improper clamping or thermal expansion mismatches can also damage the assembly.

Operational measures to maximize life and reliability

Practical practices that operators use include:

- Preheating: consistent, adequate preheat to prevent freezing and reduce thermal shock risk is critical. Preheating spares reduces changeover risk.

- Proper installation and alignment: ensure vertical orientation, correct seating, and appropriate ramming to create a gas-tight fit.

- Argon purging and controlled gas management: argon purge through the nozzle or auxiliary ports helps float inclusions away from the orifice and establishes a protective film to reduce refractory contact and sticking; purge rates must be optimized to avoid gas entrapment in the cast product.

- Monitoring: back-pressure on purge lines, mold level behavior, gas composition (nitrogen uptake) and other process indicators provide early warning of nozzle deterioration or leakage.

- Routine inspection and scheduled replacement: proactive replacement before catastrophic wear or frequent inspection during long sequences reduces unplanned outages.

- Emergency response protocols: clear procedures for partial leaks, plug detection and safe shutdown minimize risk to personnel and equipment in case of failure.

Technological advances

Recent innovations target longer life, faster changeover and lower defect rates:

- Advanced insert materials and graded composites: engineered zirconia and multi-layer inserts deliver superior wear resistance and reduced inclusion adhesion.

- Quick-change nozzle systems: mechanical changers or cartridge systems permit rapid swap-out of the lower nozzle element during production, minimizing downtime.

- Surface treatments and coatings: thin, inert ceramic coatings or engineered slurries applied prior to casting reduce inclusion sticking and initial wear.

- Optimized flow geometries: computational modeling and scale-model experiments have refined outlet shapes that produce laminar, low-shear jets and improved inclusion transport characteristics.

- Instrumentation and automation: improved sensing (pressure, acoustic, thermal) and automated control of purge and gate systems provide earlier detection and more consistent management of nozzle condition.

Conclusion

The tundish metering nozzle is a small but critical element in the continuous casting chain. Its design, material composition and operational management directly influence casting stability, product quality and overall plant productivity. Understanding the interplay among flow dynamics, refractory behavior and practical maintenance strategies is essential for metallurgical engineers and operators tasked with improving uptime and reducing casting defects. Modern developments — from advanced zirconia inserts to rapid-change mechanics and digital monitoring — continue to push nozzle reliability forward, but diligent preheating, proper installation and proactive monitoring remain the most effective tools to avoid the recurring problems of clogging, erosion and thermal failure

Tips You Shuold Know About The Tundish Metering Nozzle

Introduction To The Fast Change Mechanism Of Tundish Metering Nozzle

. Tundish Metering Nozzle&Zirconia Inserts

What Is The Composition Of Sub Entry Nozzle(SEN)

Ladle Shroud Gasket – Material, Function, Shape & Installation Guide